unitedwoodland@gmail.com

+6012-209 6689

Mon - Fri 08:00 - 17:00

GBX Rockfall Netting is generally used to prevent rocks and debris of slopes from falling on to the roads, railways, buildings and nearby public properties.

Due to its double twisted fabrication, it is strong and robust enough to resist the force of the falling rocks and unlike conventional chain-link mesh, it does not unravel should some of the wires break. Vegetation growth can be established by incorporating erosion control mat within its wire mesh and this is dependent on the slope gradient and surrounding environment.

With its ease, quick and reliable method of installation render GBX Rockfall Netting the ideal choice for project clients, consultants and contractors to adopt as it saves construction time and cost.

A. Galvanising

All wires including the PVC coated type shall be heavily zinc coated to BS 443:1982 (1990) and Class A coating in BS EN 10244-2:2001, with the minimum zinc coating weight as shown below:

3.4mm

2.7mm

2.2mm

Selvedge wire

Mesh wire

Lacing wire

275 g/m²

260 g/m²

240 g/m²

3.4mm

2.7mm

2.2mm

Selvedge wire

Mesh wire

Lacing wire

275 g/m²

260 g/m²

240 g/m²

The adhesion of the zinc coating to the wire shall be such that when the wire is wrapped six times around one wire diameter size mandrel, it does not flake or crack to such an extent that any zinc can be removed by rubbing with bare fingers.

B. PVC Coating

All wires used in the fabrication of the GBX Rockfall Netting shall be extruded with a U.V. stabilized poly vinyl chloride (PVC) coating compound. The grey coloured coating with 0.5mm average thickness and not less than 0.40mm thickness. This PVC compound shall be capable of resisting deleterious effects of natural weather exposure and immersion in salt water without much material changes to its initial properties which are:

1) Specific Gravity

Shall be 1.30 to 1.35 in accordance with ASTM D 792-91

2) Durometer Hardness

Shall be 50 to 65 Shore D in accordance with ASTM D2240-86

3) Tensile Strength

Shall not be less than 210kg/cm2 in accordance with ASTM D412

4) Elongation

Shall not be less than 190% and shall not be greater than 280% as per ASTM D412-87

5) Resistance to Abrasion

The loss weight shall not be greater than 0.19g in accordance with ASTM D142-56(75)

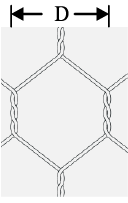

C. Wire Mesh

The average mesh width D, measured at right angles between twisted sides over 10 meshes shall conform to the tolerance limits specified in BS EN 10223:1997 Part 3:

For Mesh D= 80mm, the tolerance limit shall be 80mm +16%, -4%

* Information presented herein, while not guaranteed, is to the best of our knowledge true and accurate. While every effort has been made to provide accurate and reliable information, it is up to the user of this brochure to verify all information, including designs it might be based upon, with an independent source. Application of this data must be made on the basis of responsible professional judgement. Except when agreed to inworking conditions of use, no warranty expressed or implied is made regarding the performance of any product, since the manner of use and handling is beyond our control