unitedwoodland@gmail.com

+6012-209 6689

Mon - Fri 08:00 - 17:00

Geobuildex Reinforced Mesh

The GBX Reinforced-Mesh is a reinforced soil system for retaining wall integrating a gabion front face with a continuous sheet of double twisted wire mesh as reinforcement panel. This system is an ideal solution to problems of weak connection or junction joints which arises in other reinforced soil system.

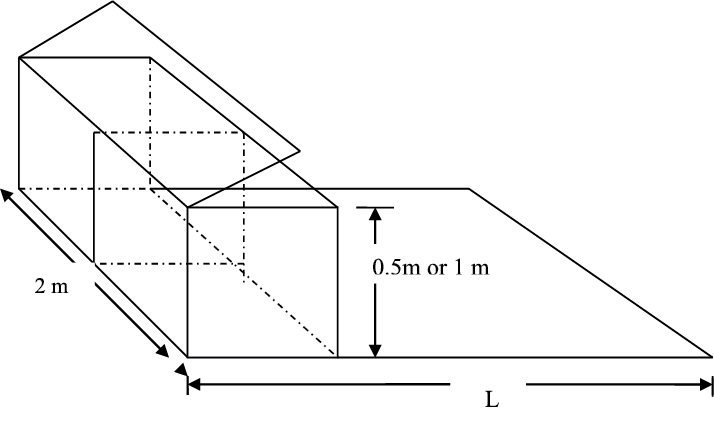

Reinforce-Mesh Sizes

W x H x L

2 x 1 x 3

2 x 1 x 4

2 x 1 x 5

2 x 1 x 6

2 x 1 x 7

2 x 0.5 x 3

2 x 0.5 x 4

2 x 0.5 x 5

Other sizes can be custom made to suit

General Description

The standard GBX Reinforced-Mesh unit forms a mesh front-facing gabion of 1m x 1m section with reinforcement mesh panel that extends from the base of the box gabion. The Reinforced-Mesh are fabricated from flexible wire mesh to accommodate significant deformation without failure. This unique Reinforced-Mesh system allows the structure to be permeable due to its permeable nature of the rockfills which eliminates build up of hydrostatic pressure behind the retaining structure.

Characteristics

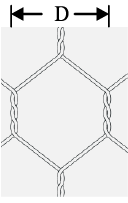

The flexible wire mesh shall be hexagonal woven mesh with the joints formed by triple-twist which does not unravel if cut.

All wires used in the manufacturing of the Reinforced-Mesh units conform to BS 1052:1980 (1999), in mild steel wire, annealed, having a tensile strength of 38-50 kgf/mm² before PVC coating and fabrication of the netting.

To ensure a well-adhered zinc coating, all wires are heavily galvanized to BS 433:1982 (1990) and conforming to its minimum weight zinc coating weight and zinc coating adhesion requirement which is checked by rigorous wrapping test.

The diameter of the wire used in the fabrication of the woven mesh shall be 2.7mm with PVC coating, extruded onto the wire core, having a minimum thickness of 0.5mm resulting in an overall nominal diameter of 3.8mm. All edges of the Reinforced-Mesh units shall be mechanically selvedge to prevent raveling of the mesh and to develop the full strength of the woven mesh.

Wire Strength

All wires used in the fabrication of GBX Reinforced-Mesh conform to BS 1052:1980(1999), in mild steel wire, annealed type, having a tensile strength of 38-50kgf/mm² and having variation limits as specified for the wire diameter.

Galvanizing

All wires including the PVC coated type shall be heavily zinc coated to BS 443:1982 (1990) and Class A coating in BS EN 10244-2:2001, with the minimum zinc coating weight as shown below:

Wire Diameter

3.5mm

2.7mm

2.2mm

Type of wire

Selvedge wire

Mesh wire

Lacing wire

Min. Zinc Coating Weight

275 g/m²

260 g/m²

240 g/m²

The adhesion of the zinc coating to the wire shall be such that when the wire is wrapped six turns round a mandrel of 4 times the diameter of the wire, it does not flake or crack to such an extent that any zinc can be removed by rubbing with bare fingers.

PVC Coating

All wires used in the fabrication of the GBX Reinforced-Mesh shall be extruded with a U.V. stabilized poly vinyl chloride (PVC) coating compound. The coating shall be grey in colour and having an average thickness of 0.5mm and not less than 0.4mm thickness. This PVC compound shall be capable of resisting deleterious effects of natural weather exposure and immersion in salt water without much material changes to its initial properties.

The PVC coating compound shall have the following initial material properties:

1) Specific Gravity

Shall be 1.30 to 1.35 in accordance with ASTM D 792-91

2) Durometer Hardness

Shall be 50 to 65 Shore D in accordance with ASTM D2240-86

3) Tensile Strength

Shall not be less than 210kg/cm2 in accordance with ASTM D412

4) Elongation

Shall not be less than 190% and shall not be greater than 280% as per ASTM D412-87

5) Resistance to Abrasion

The loss weight shall not be greater than 0.19g in accordance with ASTM D142-56(75)

Mesh Size

The average mesh width D, measured at right angles between twisted sides over 10 meshes shall conform to the tolerance limits specified in BS EN 10223:1997 Part 3: Hexagonal steel wire netting for engineering purposes as followed:

For Mesh D= 80mm, the tolerance limit shall be 8cm +16%, -4%

Geobuildex Reinforced Mesh

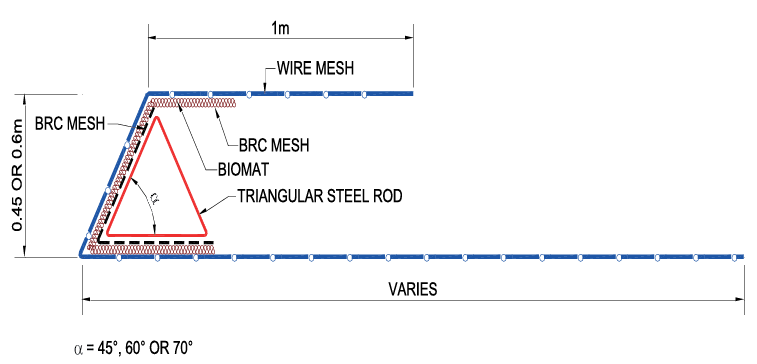

GBX Green Reinforced Mesh is a reinforced soil system for retaining wall integrating a coir front face with a continuous sheet of mesh as reinforcement panel. This system will solve the problem of weak connection or junction joints which arises in other reinforced soil system. Hydro-seeding is encouraged to provide a ‘greening’ front facing to the completed structure.

GBX Green Reinforced Mesh Sizes

W x H x L @ 45° or 60° slope

2 x 0.45 x 3

2 x 0.45 x 4

2 x 0.45 x 5

2 x 0.45 x 6

2 x 0.45 x 7

2 x 0.6 x 3

2 x 0.6 x 4

2 x 0.6 x 5

Other slope angles can also be fabricated.

Cross-section of GBX Green Reinforced Mesh

General Description

GBX Green Reinforced Mesh unit consists of PVC coated wire mesh front-facing with Erosion Control Mat (ECM) sandwiched in between the wire mesh and the BRC mesh as shown in the above diagram. The Reinforced-Mesh are fabricated from flexible wire mesh to accommodate significant to grow and the Erosion Control Mat (ECM) will prevent the seeds from being washed away.

Characteristics

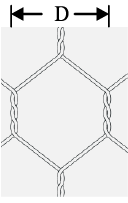

The flexible wire mesh shall be hexagonal woven mesh with the joints formed by triple-twist which does not unravel if cut.

All wires used in the manufacturing of the GBX Green Reinforced Mesh units conform to BS 1052:1980 (1999), in mild steel wire, annealed, having a tensile strength of 38-50 kgf/mm² before PVC coating and fabrication of the netting.

To ensure a well-adhered zinc coating, all wires are heavily galvanized to BS 433:1982 (1990) and conforming to its minimum weight zinc coating weight and zinc coating adhesion requirement which is checked by rigorous wrapping test.

The diameter of the wire used in the fabrication of the woven mesh shall be 2.7mm with PVC coating, extruded onto the wire core, having a minimum thickness of 0.5mm resulting in an overall nominal diameter of 3.7mm. All edges of the Reinforced-Mesh units shall be mechanically selvedge to prevent raveling of the mesh and to develop the full strength of the woven mesh.

Wire Strength

All wires used in the fabrication of Green Reinforced Mesh shall conform to BS 1052:1980(1999), in mild steel wire, annealed type, having a tensile strength of 38-50kgf/mm² and having variation limits as specified for the wire diameter.

Galvanizing

All wires including the PVC coated type shall be heavily zinc coated to BS 443:1982 (1990) and Class A coating in BS EN 10244-2:2001, with the minimum zinc coating weight as shown below:

Wire Diameter

3.4mm

2.7mm

2.2mm

Type of wire

Selvedge wire

Mesh wire

Lacing wire

Min. Zinc Coating Weight

275 g/m²

260 g/m²

240 g/m²

Wire Diameter

3.4mm

2.7mm

2.2mm

Type of wire

Selvedge wire

Mesh wire

Lacing wire

Min. Zinc Coating Weight

275 g/m²

260 g/m²

240 g/m²

The adhesion of the zinc coating to the wire shall be such that when the wire is wrapped six turns round a mandrel of 4 times the diameter of the wire, it does not flake or crack to such an extent that any zinc can be removed by rubbing with bare fingers.

PVC Coating

All wires used in the fabrication of the GBX Reinforced-Mesh shall be extruded with a U.V. stabilized poly vinyl chloride (PVC) coating compound. The coating shall be grey in colour and having an average thickness of 0.5mm and not less than 0.4mm thickness. This PVC compound shall be capable of resisting deleterious effects of natural weather exposure and immersion in salt water without much material changes to its initial properties.

The PVC coating compound shall have the following initial material properties:

1) Specific Gravity

Shall be 1.30 to 1.35 in accordance with ASTM D 792-91

2) Durometer Hardness

Shall be 50 to 65 Shore D in accordance with ASTM D2240-86

3) Tensile Strength

Shall not be less than 210kg/cm2 in accordance with ASTM D412

4) Elongation

Shall not be less than 190% and shall not be greater than 280% as per ASTM D412-87

5) Resistance to Abrasion

The loss weight shall not be greater than 0.19g in accordance with ASTM D142-56(75)

Mesh Size

The average mesh width D, measured at right angles between twisted sides over 10 meshes shall conform to the tolerance limits specified in BS EN 10223:1997 Part 3: Hexagonal steel wire netting for engineering purposes as followed:

For Mesh D= 8cm or 80mm, the tolerance limit shall be 8cm +16%, -4%