unitedwoodland@gmail.com

+6012-209 6689

Mon - Fri 08:00 - 17:00

Geobuildex Heavily Galvanised Gabion & Gabion Mattress

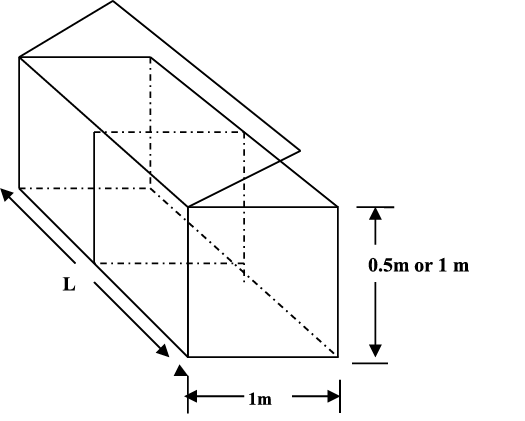

GBX Heavily Galvanized Gabions are generally rectangular basket stoutly made of hexagonal steel wire mesh strengthened by selvedges of heavier wire and by mesh diaphragms which divide it into 1m long compartments. Supplied packed flat, it is assembled on site and normally filled in situ with quarried stone or large rounded rocks. Sections of gabions are securely wired together in position to form the required retaining or anti-erosion structure.

Manufactured in a large variety of sizes and types, the gabion box and mattress units come in a wide selection of mesh and wire diameters some of which are listed below:

Gabion Sizes

L x H x W

1 x 1 x 1

2 x 1 x 1

3 x 1 x 1

4 x 1 x 1

1 x 0.5 x 1

2 x 0.5 x 1

3 x 0.5 x 1

4 x 0.5 x 1

General Description

The standard GBX Gabion units are essentially rectangular wire cages used to effectively retain rocks to serve as retaining structure as well as surface protection against erosion and scouring.

GBX Gabion units are fabricated from flexible wire mesh to accommodate significant deformation without failure. This unique system allows the structure to be permeable due to its permeable nature of the rockfills which eliminates build up of hydrostatic pressure behind the retaining structure.

Features

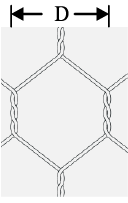

The flexible wire mesh shall be hexagonal woven mesh with the joints formed by triple-twist which does not unravel if cut.

All wires used in the manufacturing of the GBX Gabion units conform to BS 1052, in mild steel wire, annealed, having a tensile strength of between 380N/mm² and 500N/mm² to before PVC coating and fabrication of the netting.

To ensure a well-adhered zinc coating, all wires are heavily galvanized to BS 433 and conforming to its minimum weight zinc coating weight and zinc coating adhesion requirement which is checked by rigorous wrapping test.

The wire used in the fabrication of the woven mesh shall be of the finest and highest quality which ae equal to or better than those produced by other international gabion manufactures. All edges of the Gabion units shall be mechanically selvedge to prevent raveling of the mesh and to develop the full strength of the woven mesh.

For marine and polluted river works, the wires are coated with a layer of U.V. stabilized grey PVC to provide extra protection against corrosion and abrasion on top of the already heavily galvanized steel wire. Diaphragms are fixed at 1m intervals inside each cage to enhance rigidity and to prevent the movement of rockfill within the cage.

GBX Brand of Gabions offer various sizes, dimensions and combinations of gabions to suit to the site condition and designs.

GBX GABION MATTRESS

GBX Heavily Galvanized Gabions Mattress is a rectangular basket stoutly made of hexagonal steel wire mesh strengthened by selvedges of heavier wire and by mesh diaphragms which divide it into 1m long compartments.

Supplied packed flat, it is assembled on site and normally filled in situ with quarried stone or large rounded rocks. Sections of gabions are securely wired together in position to form the required retaining or anti-erosion structure.

Manufactured in a large variety of sizes and types, the gabion mattress units come in a wide selection of mesh and wire diameters some of which are listed below:

Gabion Mattress Sizes

L x H x W

3 x 2 x 0.23

6 x 2 x 0.23

3 x 2 x 0.30

6 x 2 x 0.30

Customized sizes can be fabricated.

General Description

The standard GBX Gabion Mattress units are essentially rectangular wire cages used to effectively retain rocks to serve as retaining structure as well as surface protection against erosion and scouring especially when laid along river bank or shoreline.

The Gabion Mattress units are fabricated from flexible wire mesh to accommodate significant deformation without failure. This unique system allows the structure to be permeable due to its permeable nature of the rockfills which eliminates build up of hydrostatic pressure behind the retaining structure.

Characteristics

The flexible wire mesh shall be hexagonal woven mesh with the joints formed by triple-twist which does not unravel if cut.

All wires used in the manufacturing of the Gabion Mattress units conform to BS 1052, in mild steel wire, annealed, having a tensile strength of between 380N/mm² and 500N/mm² to before PVC coating and fabrication of the netting.

To ensure a well-adhered zinc coating, all wires are heavily galvanized to BS 433 and conforming to its minimum weight zinc coating weight and zinc coating adhesion requirement which is checked by rigorous wrapping test. This carefully carried out galvanization prevents rusting when comes in contact with air or moisture especially when installed in submerged area.

The wire used in the fabrication of the woven mesh shall be of the finest and highest quality which ae equal to or better than those produced by other international gabion manufactures. All edges of the Gabion Mattress units shall be mechanically selvedge to prevent raveling of the mesh and to develop the full strength of the woven mesh.

For marine and polluted river works, the wires are coated with a layer of U.V. stabilized grey PVC to provide extra protection against corrosion and abrasion on top of the already heavily galvanized steel wire. Diaphragms are fixed at 1m intervals inside each cage to enhance rigidity and to prevent the movement of rockfill within the cage.

Vegetation growth can be established by incorporating erosion control mat within its wire mesh and this is dependent on the slope gradient and its surrounding environment to ensure greeneries with the flourishing of flora.

GBX Heavily Galvanized Gabion & Gabion Mattress Technical Date Sheet

A. Tensile Strength & Galvanising

All wires used in the fabrication of GBX Gabion mattress shall conform to BS 1052, in a mild steel wire, annealed type, having a tensile strength of 38-50kgf/mm² and having variation limits as specified for the wire diameter. All wires including the PVC coated type shall be heavily zinc coated to BS 443 and Class A coating in BS EN 10244-2, with the minimum zinc coating weight as shown below:

Wire Diameter

3.5mm

2.7mm

2.2mm

Type of wire

Selvedge wire

Mesh wire

Mesh wire/Lacing wire

Min. Zinc Coating Weight

275 g/m²

260 g/m²

240 g/m²

Wire Diameter

3.5mm

2.7mm

2.2mm

Type of wire

Selvedge wire

Mesh wire

Mesh wire/Lacing wire

Min. Zinc Coating Weight

275 g/m²

260 g/m²

240 g/m²

B. PVC Coating

All wires used in the fabrication of the GBX Gabion and Gabion Mattress shall be extruded with a U.V. stabilized poly vinyl chloride (PVC) coating compound. The grey coloured coating with 0.55mm average thickness. This PVC compound shall be capable of resisting deleterious effects of natural weather exposure and immersion in salt water without much material changes to its initial properties which are:

1) Specific Gravity

Shall be 1.30 to 1.35 in accordance with ASTM D 792

2) Durometer Hardness

Shall be 50 to 65 Shore D in accordance with ASTM D2240

3) Tensile Strength

Shall not be less than 210kg/cm2 in accordance with ASTM D412

4) Elongation

Shall not be less than 190% and shall not be greater than 280% as per ASTM D412

5) Resistance to Abrasion

The loss weight shall not be greater than 0.19g in accordance with ASTM D1242

C. Wire Mesh

The mesh tensile strength shall be 47kN/m, meanwhile the average mesh width D, measured at right angles between twisted sides over 10 meshes shall conform to the tolerance limits specified in BS EN 10223 Part 3:

The type of mesh size used is D= 80mm with tolerance limit of ±10%.